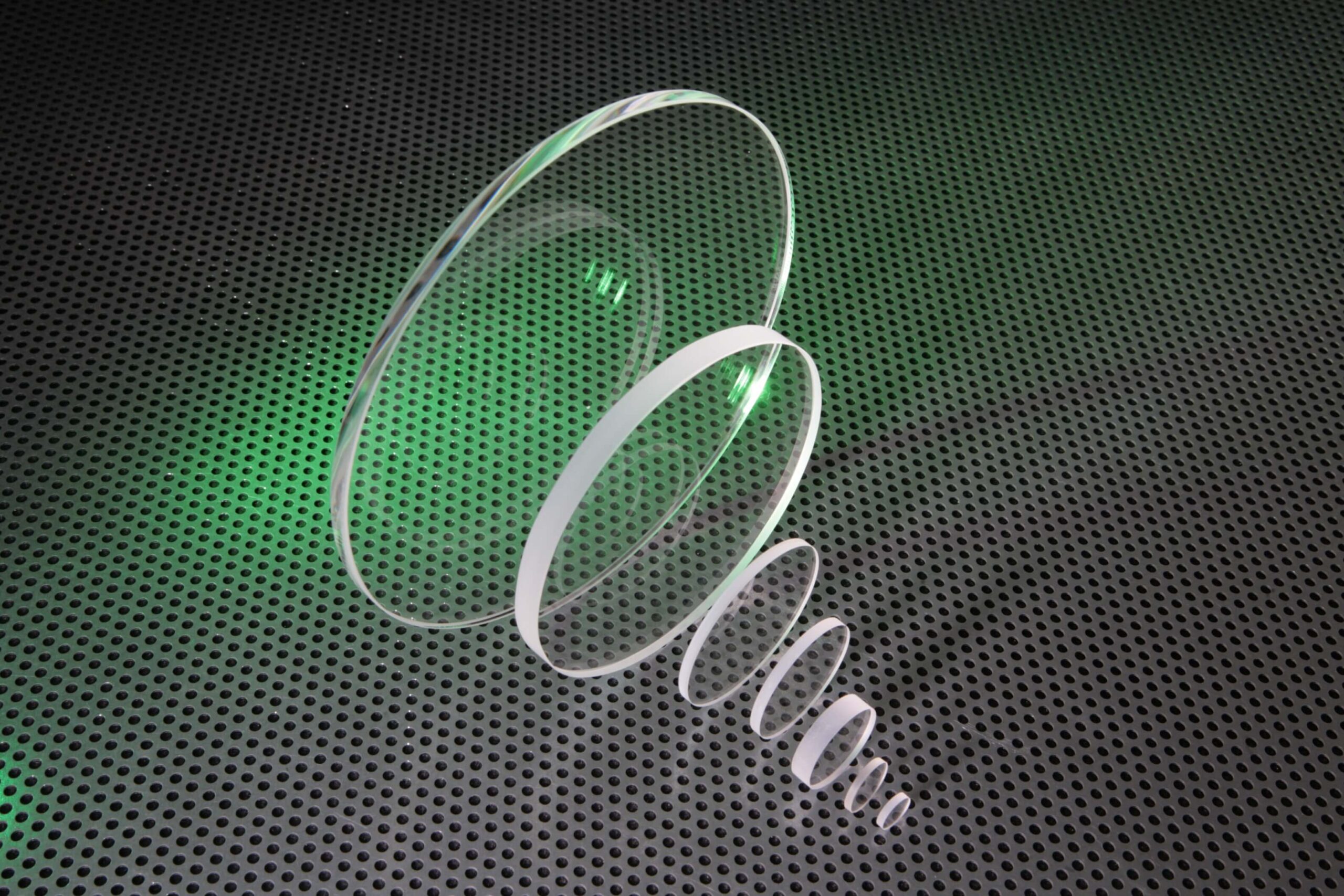

In Optical Windows production, Fused silica is a very important in its production. This non-crystalline synthetic amorphous silicon dioxide of extremely high purity gives maximum transmission from 195 to 2100 nm. It is a colorless silica glass that combines a very low thermal expansion coefficient with good optical qualities, and excellent transmittance in the ultraviolet region. Transmission and homogeneity exceed those of crystalline quartz without the problems of orientation and temperature instability inherent in the crystalline form. It will not fluoresce under UV light and is resistant to radiation. For high-energy applications, the extreme purity of fused silica optical window eliminates microscopic defect sites that could lead to laser damage. Compared with other optical glasses like N-BK7, Fused Silica has a very low autofluorescence and scattering. The fused Silica windows have a low distortion capacity, with high or excellent parallelism, low bulk scattering, and fine surface quality which in turn makes them perfectly suited for a wide variety of demanding applications, including multiphoton imaging systems and intracavity laser. Fused silica is one of the commonly used materials in glass used for manufacturing of lenses fabrication operations. Its unique properties make them suitable for use in fabricated glass components. It is the purest form of glass on the market, both structurally and physically. Its cross-linked three-dimensional structure results in exceptional thermal resistance and near-zero thermal expansion.

Benefits Of Fused Silica Optical Windows

- Since it is synthetically processed, it is the purest form of glass on the market, both structurally and physically

- It has chemical purity and resistance

- It is resistant to radiation

- It is transparent from ultraviolet to the infrared spectral range

- It has low thermal expansion and high thermal shock resistance

- High softening point and strong thermal resistance

Application Of Fused Silica Optical Windows

Electronics

Fused silica is used in electronics and electronic technology for its conductive and insulating components. The fused silica is ideal as a construction material as it offers low conductivity, high penetration field strength, and low electric loss within the system.

Chemical and pharmaceutical processes

Fused silica is used in most pharmaceutical and chemical manufacturing operations, it has a wide range of conditions, including exposure to high temperatures, corrosive chemicals, and water. Because they are chemically pure, chemical resistant, and thermally stable makes they are suitable to be used in this sector.

Ultraviolet Light Sanitizer

This is where the fused silica optical window comes into play as it serves as a non-toxic alternative to disinfection and sterilization procedures. The fused silica demonstrates a high thermal and radiation resistance, which makes them suitable for use in equipment subjected to such operations, such as semiconductor components and medical, laboratory instruments, and surgery equipment.

Semiconductors

Semiconductors need the purity of two materials to be at it’s best as it has a wide range of use.

Optical System Components

Fused silica here has another application in optics as an optical window as it is used to manufacture many optical parts such as lenses, mirrors, UV and IR transmitting optics, and metrology components due to their ability to transmit light in the visible, infrared, and ultraviolet.

Laser Technology

Lasers’ lighting system relies on this Fused Silica Optical Windows to focus or separate light to perform their operations. co2 laser beam optics is used for cutting.

High-Temperature Operations

The thermal properties of fused silica allow it to withstand high processing temperatures without risk of damage or degradation.